Welding

Welding with MIG / MAG method

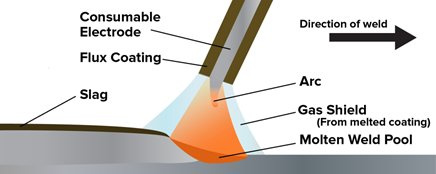

In this welding method, the molten electrode is protected from the effects of the ambient atmosphere (mainly oxygen and nitrogen) by a protective atmosphere that may be inert or active. Inert atmospheres do not enter chemical reactions with the melt bath. The active atmospheres are involved in the chemical reactions in the melt pool, their action being compensated by the appropriate composition of the additive material.

MIG welding is a melt electrode welding in a gas shield provided by an inert gas such as helium or argon.

MAG welding is a welding electrode in the gas protection provided by the chemically active gas CO2 and its mixtures.

Protective atmosphere welding has numerous applications in the industry, where high productivity and work efficiency are required, because of its financial availability and the wide choice of welding auxiliary materials, it is one of the technologies that are most widely used in engineering.

Advantages:

- Excellent productivity

- Possibility to weld in all positions

- The possibility of automation and robotization

- working environment hygiene

Drawbacks:

- the need to ensure a continuous supply of inert gas (to prevent the atmosphere from being blown off by eg drafts or weather conditions)

- Susceptibility to the formation of imperfect welds such as e.g. cold joints and non-joints

- Demanding implementation of automation and serial production requirements

Welding with TIG / WIG method

TIG / WIG stands for electric arc welding using a non-melting electrode and an inert gas shielding atmosphere. The electric arc burns between the non-melting electrode and the welded material. The electrode must be made of a material resistant to very high temperatures. Most often, it is tungsten, where the tungsten electrode is clamped in the torch head by forceps. Through it, a welding current is injected into the electrode. The burner is provided with a nozzle through which gas flows and this creates an inert protective atmosphere.

Such welding can be done either by melting and casting the base materials or by adding additional material of similar composition to the base material. TIG welding can be done manually, semi-automated or robotic - fully automated.

TIG welding is used in demanding welding of pipe layers, in more complicated structures, or in metal constructions where its decoration is emphasized, as well as in special materials, but stainless steel, aluminum and nickel are the main applications.

Advantages:

- výborná kontrola a ochrana zvarového kúpeľa

- možné zváranie bez prídavného materiálu

- nedochádza k tepelnému ovplyvneniu základného materiálu

- možné dosiahnutie veľkých hrúbok zvarov

- prísun tepla je možné regulovať

- možnosť zvárania v rôznych polohách (zváranie potrubí)

- možné zváranie aj veľmi tenkých materiálov

Drawbacks:

- The technical complexity of the device, especially when welding with alternating current also brings increased economic demands

- Low productivity especially for manual welding due to precision, which is on the other hand its biggest advantage

Pulse Arc

This is a controlled arc transfer in "Spray Arc" mode coming with it a number of advantages - such as high melting speed and the absence of machine operation of the material (at very low current levels when the weldment is not heated too much), similar to Short Arc . Each current pulse corresponds to the separation of one single drop of electrode wire, the event occurs with a regular wire feed rate (depending on its diameter). Typical frequency values are 30-300 Hz. Application: carbon and low alloy steels, stainless steel, aluminum and its alloys. (Application: Welding in various positions, weak to moderately heat-resistant materials (aluminum and its alloys) - also for material thicknesses below 3 mm.